The following general notes and advise may answer some of the questions I am asked on a regular basis about 3:1 exhaust systems that are currently in use on BSA/Triumph racing Triples.

The exhaust pipes are 1, 1/2" outside diameter, of 18 gauge material. They are proven to be most effective at 29" length, measured on the centerline of the pipe from the outer end of the exhaust stub to the end of the pipe. On some machines this length is difficult to achieve and longer pipes have to be used. Testing of pipes up to 32" have shown a little change in power output with the shorter pipe giving more 'top-end' power and the longer pipe a little better 'mid-range' The differences are, however, small.

The collector has proven to be best in a triangular form. 'Flat' collectors did not seem to behave well under test. The collector currently used has a taper about 4" long from the end of the nest of pipes and an outlet diameter of 2". A 'steeple' is fitted within the collector. 'Works' collectors had an outlet of about 1, 5/8" and this was a piece of pipe of about 4" long, before the megaphone. Currently the megaphone is attached directly to the collector.

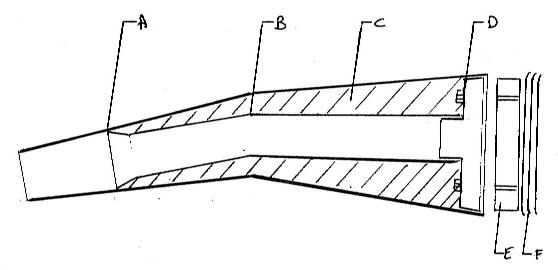

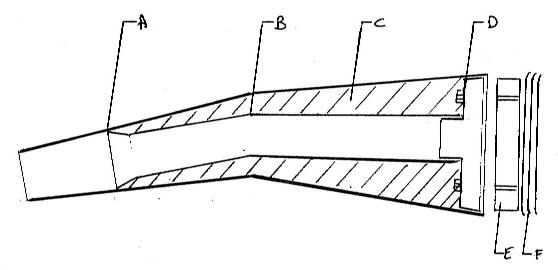

Megaphones of 24" to 29" long are used, with a gentle taper from 2" to 4" diameters. They may be straight or cranked. To reduce the noise output absorption techniques are used. Perforated pipe at 2, 1/4" diameter is fitted within the megaphone and the space between the perforated pipe and the megaphone is packed with silencer packing. A larger diameter perforated pipe will allow more noise, conversely a smaller one will give less noise. It is most important that the perforated pipe either contacts directly the outer skin of the megaphone, or a small reverse cone is fitted to the perforated pipe that itself contacts the wall of the megaphone. A flat closure within the megaphone results in running difficulties. The external end closure system used should be removable to allow periodic repacking of the silencer.

Also, at the external end of the perforated tube an arrangement can be made to carry discs and end cones produced by the 'Supertrap' company. These have been found to be effective in reducing the noise output and changing the note too so that it is a little less obtrusive.

Testing of both the absorption system alone, and with the addition of the Supertrap end cones, has shown no reduction in power output, and in a number of cases a small increase was seen.

A) Drill 3 holes through the megaphone wall to allow plug welding of the perforated pipe into place. The perforated pipe shown has been enlarged at this end to act as a small reverse cone and to ensure a good joint with the megaphone with no wall across the megaphone to disturb gas flow and pressure waves.

B) If the megaphone is cranked then the perforated pipe must be cranked to the same angle.

C) Sound absorption material.

D) Closing plate, shown with nuts fitted internally to allow the fitting of E. Once the closing plate is fitted about 2mm below the end of the megaphone, roll over the end of the megaphone to secure the closing plate in place. The closing plate should be made to be a good fit inside the perorated pipe and not joined here, as removal is required to allow repacking.

E) Is a suggested mounting ring, secured by screws (preferably countersunk) to allow fitting of additional equipment, such as:

F) Supertrap discs and end cones, which are secured by screws into the mounting ring.

Triple Cycles

Copyright © 2004 Philip Pick

Version 0.1 Date June 2004